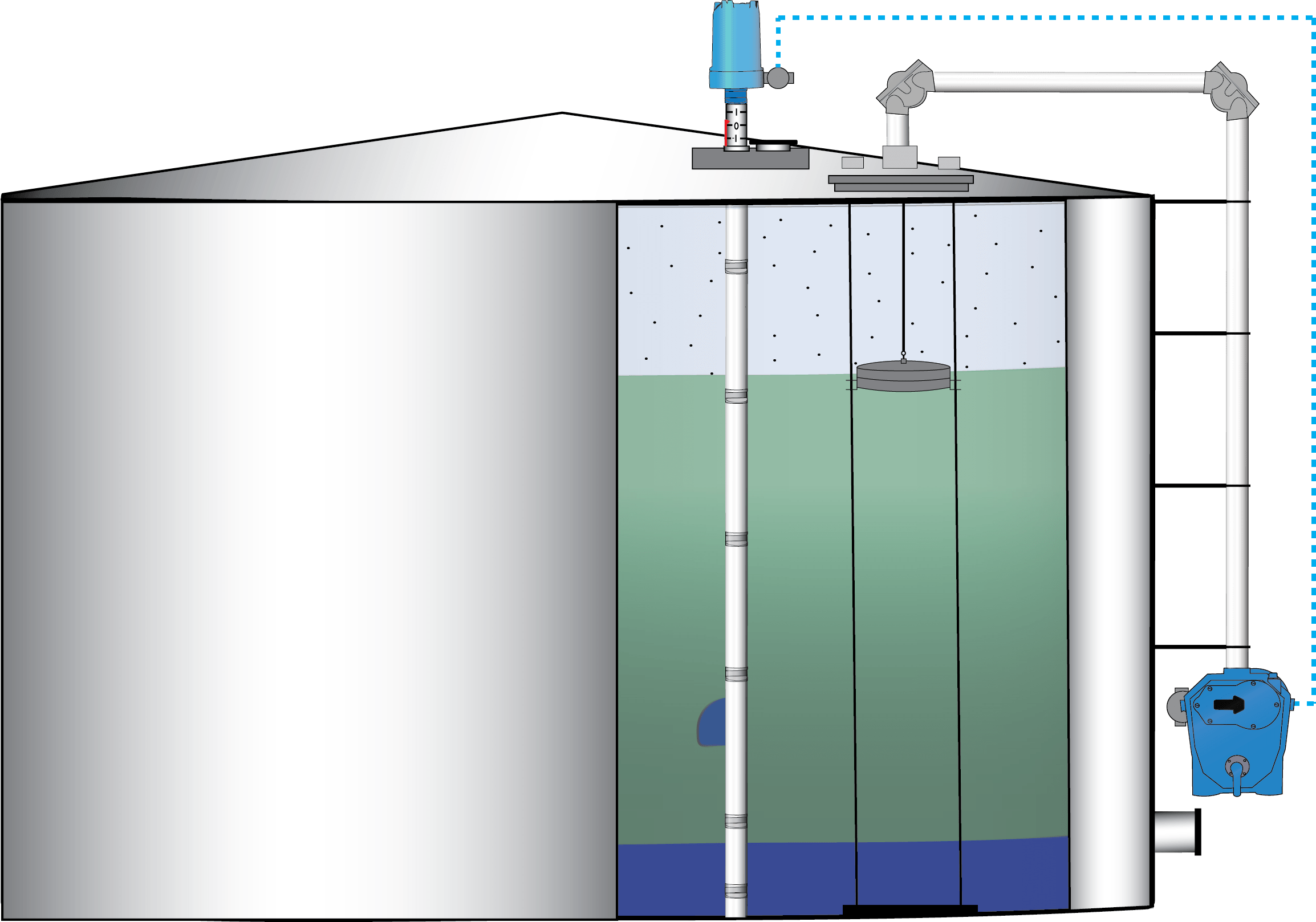

GSI 3025 Multi-function Tank Probe

- Volume (Hybrid or Hydrostatic)

- Multi-point Spot Temperature

- Multi-strata Density

- Total Water (Free, emulsified, & Entrained)

- Product Quality via real time Sam-pling

- And other available data

- One probe, No gauge well required

Rupture Prevention ( Tank Over pressure and Vacuum)

Optional— Overfill Prevention (API 2350 4th Edition)

Your mechanical gauge with our transmitter (card), a 3025 MTP, good field wiring, and STGP Software = High Accuracy Inventory!

A customer wanted to improve the accuracy to achieve better volumes from their existing mechanical (Tape & Float) gauges and transmitters for loss control purposes. Every vendor they spoke with went to the replacement of the gauges with Radar or other technology and wireless communications.

GSI proposed the following: Use your existing mechanical tank gauge with a GSI 2000 transmitter using existing protocol (Personality Module) and field wiring (if it is in good condition) and add the GSI 3025 MTP to get Multi-point spot temperature, Average product temperature, Multi-strata density, Average product density, Total water (Free, emulsified, and entrained), and Volume. The existing tank gauging system protocol or modification to MODBUS RTU protocol would allow this additional data to your host system. GSI can also upgrade your existing software to allow for accurate volumetric Inventory. Accurate Volume, product quality, and Inventory net worth at a lower cost.