“MTG” Compared to other Technology

Tank owners should first evaluate what information (measured or calculated) they need from the products they store and to what installed measurement accuracy should each parameter provide. What capabilities does each gauge offer and what benefits does it provide, segregate fact from advertised fiction, and develop a list of needs.

Example: Inventory (or buying & selling of petroleum product) is based upon the measurement of Volume within a tank, by either Hybrid Method (API MPMS 3.6, etc. – Level, Temperature, Density, and Water) or Hydrostatic Method (API MPMS 16.2, OIML R-125, etc. – Mass, Density, and Water). The MTG provides Volume by both methods and multiple standards. Buying and selling of petroleum product is also based upon the product quality, the sampling and measurement of density, water, and impurities over the tank height (within stratified or clean product). Note: OIML R-85 is not a Volume Standard and doesn’t provide any measurement of product quality for the buying and selling of petroleum product.

People get confused when manufacturers advertising and provided specification are based on EU measurement standard (OIML R-85) for Level. People don’t understand what was tested, i.e., the level measurement of water within a plexiglass tube located inside a laboratory? Question: How does this relate to the Installed Level Measurement Accuracy on a bulk petroleum storage tank? Considering the changes in level due to different tank types, mounting flanges, product, temperature, stratification of product density, ambient conditions, etc. Except for the EU, OIML R-85 standard doesn’t apply.

It doesn’t make sense for RTG manufacturers not to specify standards for all (Volume) parameters directly effecting Level Accuracy, i.e., such as Temperature, Density, and Water? Why don’t RTG manufacturers advertise meeting standards for Volume by Hybrid Method (API MPMS 3.6)?

Note: Why do manual reference hand lines with certified tapes show 1mm or 1/16” graduations and not 0.5mm?

MTG provides Bottom Referenced Measurement (INNAGE) or how much liquid is within the tank, i.e., not to be confused with the measurement of distance (air space) between the liquid and mounting flange, less dead space required per type of antenna, referred to as Outage. MTG can also provide Outage measurement calculation.

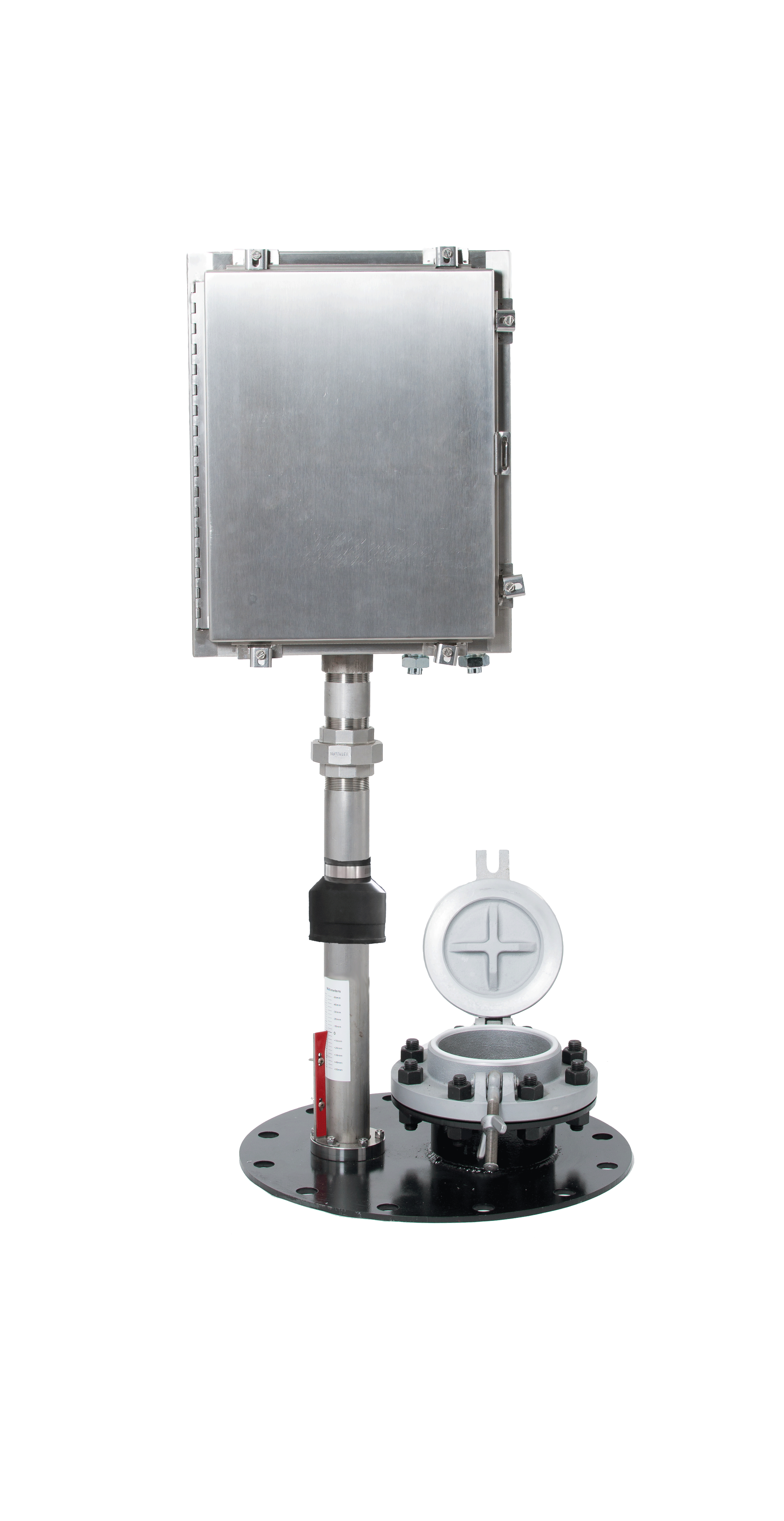

The Multi Function Tank Gauge comes with a “Tank Reference Movement Indicator (TRMI)” that shows the change of the reference measurement height from the top mounting flange to the tank bottom or datum plate when emptying or filling liquid. The TRMI is provided as a tank top indication or optional remote indication. Some are surprised by the amount of movement that occurs on actual tanks, new or old. The use of the reference flange height directly taken from the Tank Strapping Table can result in measurement error, thus, TRMI and manual hand line reference measurement (API MPMS 3.1A) should be used for accurate measurement.

MTG “Multi-function Tank Gauge” calculates Volume by both Hybrid and Hydrostatic Methods to custody transfer accuracy. MTG is self-calibrating after initial installation off-set, i.e., some RTG’s are factory calibrated. How does factory calibration relate to the installed gauge accuracy on the tank?

All parameters for the measurement or calculation of Volume from one MTG, i.e., not three or four instruments, gaugewells or flanges, conduit, wiring, spare parts, calibration etc. How do you calculate level from the non-matching reference heights of each gaugewell?

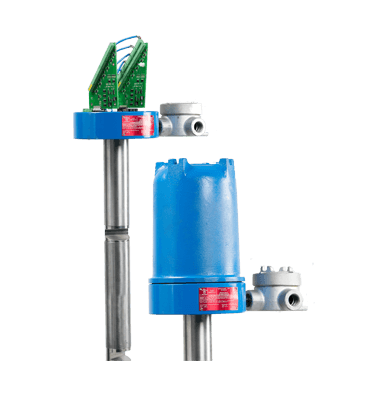

Because MTG comes in direct contact with the liquid, it has numerus advantages over non-contacting Radar, Ultrasonic, and Sonar tank gauges in the accurate measurement of all volume parameters (Temperature, Density, & Water), product stratification, and additional information. Note: Some RTG systems claim non-contact measurement of level (air space), but then use multiple instruments in direct contact with the liquid for Volume measurement. Is this an advertising shell game?

Dependent upon the engineered configuration, MTG can provide Product quantity & quality, Overfill & Rupture Protection, Vapor Monitoring, Leak Detection, Product Stratification (Temperature, Density, and Water) and when combined with TG SOFT Server (Software), applications such as Historian, Diagnostics, Calibration, Vapor Monitoring, Leak Detection, Transfer Ticketing, Yield Analysis, Sampling, In-Tank Blending, De-Watering, PRV Monitoring, Roof weight (Rain or Snow), etc. are available. Thus, MTG’s data provides a competitive advantage and short-term payback on the investment.

Most tank gauging systems advertising custody transfer accuracy only communicate Five (5) data registers. Volume, Level, Average Temperature, Reference Density, and Free Water from multiple instruments and multiple tank entries(gaugewells). Note: The cost of an additional gaugewell will be much more expensive than the cost of the tank gauge(s) being installed. Because the tank gauge needs to be calibrated and accuracy verified in comparison to the reference, i.e., manual hand lines, electronic temperature measurement, and liquid sampling (Density & Water) from the same location in the tank.

Most wireless tank gauging systems poll one tank at a time and are relatively slow even when communicating only five registers. This is due to the processing of multiple readings to insure a repeatable reading of the level. Note: Most wireless tank gauging systems require wire and conduit for the connection of multiple instruments and power in addition to the “wireless” radio for signal. So which shell is the pea under?

The MTG “Multi-function Tank Gauge” normally provides Three-hundred and Seventy-five (375) usable data registers from one instrument from the same reference point or gaugewell as the manual hand line. Why? Because accurate measurement of Volume requires more information and not just limited information due to the technology or communications method.

Note: if you are going to run cable and conduit for power to the top of the tank, the cost of running additional cable for signal is not expensive (in comparison with the cost of additional gaugewells, i.e., taking a tank out of service, cleaning it, gas freeing it, safety inspection, hot work permits, gaugewell fabrication, structural tank modifications, roof modifications, access location on tank top (gauge platform), closing up the tank, gauge and additional instruments installed, electrical conduit, hydrostatic (water fill) testing, new tank tables, and calibration of all instrument for installed accuracy. Run the cable or Fiber, conduit or tray cable, for current and future needs, added security, and both the amount & speed of data throughput.

So, if you see a vendor specification that lists only one parameter (Level) for measurement to custody transfer accuracy, then they haven’t figured out that petroleum products are bought or sold by Volume. A well written tank gauging specification will require accuracy standards for all parameters for measuring or calculating volume. Have you found the pea yet?

- Does Volume change when using Average Temperature, three-wire RTD’s, thermistors, or IC’s are used vs. Multi-point spot temperature, Class A or Din, 100 Ohm Platinum, Four-wire RTD’s?

- Does Volume change when ground temperature and the liquid temperature of the bottom three feet (1m) isn’t measured?

- Does a 1-degree (Fahrenheit) change in temperature on most products change level more than the stated difference in level accuracy between an RTG and other technologies?

- Does Volume (and quality) change when measuring stratified product when using no density or reference density vs. multi-strata density?

- Does Volume and quality change when using free water vs. total water percentage (free, emulsified, and entrained) by strata?

In short, the standard MTG “Multi-function Tank Gauge” provides more usable data from a single instrument than any other tank gauge on the market. MTG provides the following measured and calculated parameters: Volume, Level, Multi-point spot temperature, Average product temperature, Product head mass, Product heel mass, Product mass, Product apparent mass, Total measured mass, Water mass, Total estimated mass, Multi-strata density, Average product density, Percentage of water by strata, Free water, Emulsified water, Entrained water, Stratification of product by temperature, density, and water, Vapor (pressure, temperature, density). An optional sensor is available for ambient (pressure, temperature, density) (see MTG 3013).

Click Here to see the MTG Multi-function Tank Gauge Drawings